CubeFreight

Tale of the Tape: CubeFreight and the Future of Freight Dimensioning

For years both LTL freight companies and shipping departments have struggled to properly weigh and collect dimension data on palleted shipments to ensure that correct pallet information is stated on waybills. As the freight industry expands its services to reflect the needs and concerns of all shipments, dimensioning is factoring more and more into rate calculation and therefore must be properly stated on waybills. That leaves both freight companies and shippers in a race against time.

Until now the only way to properly state shipping weight and dimension were the use of floor scales and a measuring tape. By far the most accepted method as it provides both weight and dimension, and requires no investment other than time. However, it is time that leaves almost all LTL freight carriers looking for a better way. The amount of time it takes to pick up a pallet on the cross dock, travel to the closest floor scale and then run a tape measure the height of the pallet simply cannot be consistently performed and still keep pace with shipping time standards. Lest frequently used due to significant cost and spacial concerns are the use of static dimensioning scanners mounted to the ceiling above a floor scale. While the static dimension systems automatically capture the dimension data with weight output the bulky systems create a difficult travel path for cross docks with several lift trucks and still do not meet freight shipping time standards.

Integrated Visual Data Technology has been manufacturing on-board lift truck scales for over 30 years and now provides CubeFreight technology to its SkidWeigh Plus on-board systems.

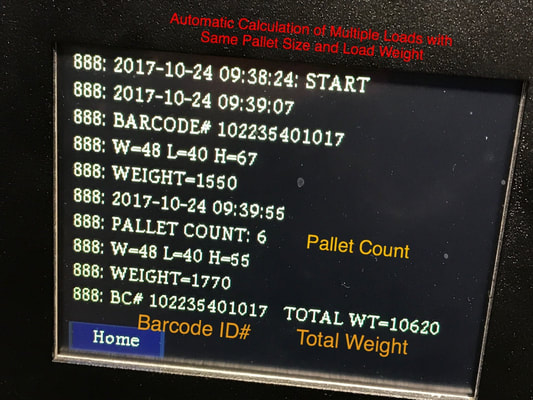

Introducing CubeFreight allows both freight carriers and shippers to accurately get the weight of the palleted shipments and match and record the dimensions of the load as well without the operator ever leaving the lift truck. This shipment data can be collected against a pro number or waybill in less than 10 seconds without out the need to move the pallet from its most efficient path to or from the staging area or trailer. CuberFreight works with scanners, printers and can also work wirelessly via RF communication to send load data in real time to a network connection.

Challenges in the LTL Freight Industry

Time

Currently most of the LTL industry uses floor scales and the labor intensive process of manually measuring pallets as a way to check against waybill errors.

The reality is the volume of pallets far exceeds the ability to capture and correctly account for all pallet shipments. Without a practical all inclusive on-board solution the manual process is just not realistic to achieve This leaves most LTL freight companies either scratching the surface or in many cases without a checking process at all.

Consider the following steps that must be performed to properly check weigh and account for DIM?

- Retrieve pallet from trailer with forklift

- Drive forklift with pallet to floor scale

- Obtain weight from floor scale

- Use a tape measure to gather the dimensions of the pallet

- Manually fill in paper work associated with pallet

- Drive forklift with pallet to staging area

- Hand in paper records at shifts completion

Space

Industrial square footage and the typical layout of most cross docks and 3PL facilities provide a considerable challenge for freight companies trying to perform weight and dimension checks. With multiple truck loading/unloading dock doors and centralized staging areas lift truck activity is happening side by side with quick shuttles to and from the staging areas. Cross dock design and staging allocation are coordinated so that quick and safe lift truck usage is achievable. Introducing centralized floor scales and static dimensioning systems is disruptive to the safe and effective process of loading and unloading pallets.

- Additional time required to travel to weight and dimension station

- Traffic jams in peak periods of product flow

- Vehicle collision as a result of additional travel

- Requires additional people to attend the weight and dimension station

- Static dimension stations require considerable amount of square footage which competes for product placement on A,B and C level staging

- Additional cost associated with weight and dimension stations

- Additional cost of lift truck maintenance due to additional time and travel

Challenges in the LTL Freight Industry

Expensive and complex freight verification systems rely on return on investment strategies to provide end users with cost reasoning for moving forward. The reality is that almost all of the return on investment strategies are in fact just that, strategies, that stand up only as a model on paper. When confronted with the reality of freight operations and real life on the cross dock conceived calculations often fall short. Any sustainable freight verification system should be practical in that it provides a solution that improves not impedes the verification cycle and that variance specifications remain constant through out the process.

Floor Scale and Tape Measure

This form of freight verification is often deployed without recourse to an R.O.I. because it does not at first show a tangible capital investment. However, when you factor the cost of time and labor towards achieving freight verification objectives it clearly becomes a strategic spend against an operating budget. The problem lies in the additional cost of labor for dedicated dimension collectors and the time required to bring the load to the weigh station. This along with the fact that during peak periods of volume it is not sustainable prove this option provides no gain.

Lift Truck Onboard Load Cell Weighing Systems

Load cell systems are basically on board check weighing scales that claim 'legal for trade accuracy'. On paper the R.O.I. shows distinct possibility over time even with the high cost of equipment and installation costs. However the technology is simply not suited for cross dock applications and requires costly and frequent calibration service in order to maintain. Initial cost along with technology that is to sensitive for the application lead to abandonment.

CubeFreight: The Evolution of Freight Weight and Dimension Verification

Integrated Visual Data Technology has been providing the freight industry check weighing scales for over 30 years. Across North America many freight carriers have come to rely on IVDT for practical and reliable check weighing scales as well as the ability to incorporate customized process orientated variations that help with time efficiency. As the freight industry has already established a definitive need to incorporate dimensioning into verification processes only IVDT's CubeFreight provides a time effective, all inclusive, and integratabtle solution. Eliminating multi-step processes, delivering a safe and effective on-board solution CubeFreight is the only system that provides both freight carriers and shipping departments a complete start to finish freight verification tool that stands up against time and delivers a real R.O.I.

Engineered for the Freight Industry CubeFreight is the Complete Solution

Fast, Efficient, and Realistic

With the challenges faced by the LTL freight companies at the forefront of the CubeFreight design, this system provides the only inclusive on-board verification option available. The CubeFreight verification process begins on the lift truck and ends on the lift truck with no need for additional equipment and or the requirement of travel. Understanding that seconds matter the CubeFreight system begins at the location of the load and within 10 seconds allows for the capture of weight and dimension for future cross reference.

- Eliminated is the time consumptive need for unnecessary travel.

- With the entire data process scaled down to approximately 10 seconds, freight verification volumes are significantly increased.

- Staging, storage and pallet movement planning is more effective.

- CubeFreights inclusive process improves operator safety and reduces vehicle damage by eliminating multiple usage steps.

- ubeFreight +/- 1% or better of vehicle capacity complies with ISO standards and is sustainable for freight check weighing.

- CubeFreight captures dimensioning measurements as trade legal as a tape measure in a fraction of the time.

- Installs on any vehicle in approximately 2 hours.

- High operator acceptance rate as process is designed for automatic input.

- Fast, Efficient and Realistic Return on Investment

Right From the Start Shipping Departments Get it Right with CubeFreight

Simple, Integrated and Accurate

LTL freight effectively begins in the shipping departments of millions of businesses throughout North America. Quite often shipping departments are understaffed and not properly equipped to provide LTL carriers with the correct weight and dimensions of the out bound freight. The result is re-invoicing from the carrier only to hit an operating budget weeks and months after it has left the source. All shipping departments that utilize a lift truck or electric pallet truck can now cost effectively integrate a CubeFreight to ensure correct weight and dimension coordinates. Within seconds a single operator can determine all that is required to ship and even print out barcoded labels for continued sort at the cross dock.

- Accurate outbound invoices.

- Can integrate with current shipping process and or become stand alone complete shipping system.

- CubeFreight provides all shipping log data in a number of easy access sources.

- With the entire data process scaled down to approximately 10 seconds, freight preparation volumes are significantly decreased.

- Staging, storage and pallet movement planning is more effective.

- Eliminates the need for unnecessary travel to a floor scale or static dimensioning device.

- CubeFreight +/- 1% or better of vehicle lifting capacity complies with ISO standards and is sustainable for freight shipping.

- CubeFreight captures dimensioning measurements as trade legal as a tape measure in a fraction of the time.

- Installs on any vehicle in approximately 2 hours.

- High operator acceptance rate as process is designed for automatic input.

- Simple, Integrated and Accurate

CubeFreight provides LTL and General Shipping departments with two complete data systems

ED3-LTL-WD

The CubeFreight ED3-LTL is the perfect system for smaller fleets or general shipping departments where time sensitivity is manageable. The ED3-LTL system provides end users with the complete automatic weight and dimensioning process and records all data for USB export. Pro numbers or waybill information is conveniently provided for in a manipulatable .csv excel file. The ED3-LTL-WD is also capable of supporting both scanners and printers for quicker input and record printing.

ED4-LTL-WD

The CubeFreight ED4-LTL-WD operates on a wireless communication platform that connects directly to your network to provide all freight and shipping data automatically. Free of cumbersome and costly wi-fi and or cloud based technologies the ED4-LTL utilizes a Base Station communication hub to collect, archive and present data in convenient forms such as ftp, LAN webpage and USB report back up. The ED4-LTL-WD along with the Base Station eliminates timely steps in obtaining critical data and puts it at your finger tips. The ED4-LTL-WD is also capable of supporting both scanners and printers for quicker input and record printing.

Accessories

Designed to maximize efficiency CubeFreight provides a number of accessories to enhance the shipping process.

Pallet Height Indicators & Scanners and Printers

Turn Electric Pallet Trucks into Mobile Weight and Dimension Stations

ED4-LTL-EP

CubeFreight is designed for all material handling vehicles with a lift device including electric pallet trucks of all capacities. With Class III trucks comprising over 30% of all lift trucks sold in North America electric pallet trucks are moving the majority of palleted loads on a daily basis. Create a more efficient, dynamic and productive pallet truck process by eliminating multiple vehicle lifting, floor scale drive zones and extra steps with CubeFreight. Turn your electric pallet truck one into a one stop shipping system.

Pallet Height Indicator

PHI-72", PHI-96"