How Much Does Safety Really Cost?

Three Ways NOT Having a Reliable Pre-Shift Safety Program Will COST You

When it comes to pre-shift safety checks and the compliance and governance of OSHA, we are all subject to the same rules and regulation. Whether you are manufacturing, distribution, logistics, wholesale retail, whatever your industry that you participate in you are responsible for ensuring that your forklifts and material handling equipment are compliant with OSHA regulation.

Which is to ensure the following is upheld and accounted for. Equipment like but not limited to forklifts are in safe working order before the commencement of a work shift, daily, rolling 8 or continental. Checks must be performed with a combination of visual and operational test checks. All defects observed must be recorded and reported. While not specific to the format OSHA requires that historical records be stored to determine that in fact compliancy by the organization is being observed and upheld, fundamentally ensuring the safety of the employees.

Then why is that so many companies struggle to maintain safe and consistent practices when it comes to following OSHA pre-shift safety regulation. The consensus is a reliance on operators and the combination of human error including negligence, paper documentation and finally the fact that there is no legal or monetary liability for those tasked to perform the safety check. All punitive and correctional assessments are levied on operational management and subsequently the organization. So, what’s at stake?

(1)Violations Resulting in Fines

OSHA ranks findings into various types which are ranked, Other than Serious, Serious, Willful and Repeat. Factoring in everything from circumstances that are likely not to cause death to those that. This evaluation systems accounts for historical behavior that assigns a ranking and subsequently a fine that can range from $15,625.00 for less serious up to $156,259.00 for more serious infractions. Just think of the cost of repeating a non-compliant safety program over time on a small fleet of 20 lift trucks.

(2)Insurance Premiums

While OSHA does not directly dictate insurance rates it certainly does have an impact. Insurers assess risk on factors like past claims, safety records and overall risk profile. OSHA safety compliance can result in lower premiums. Conversely repeated violations

or serious incidents during an inspection can result in higher premiums or even worse non coverage or refusal to insure. Beyond penalties non-compliance can also lead to other costs like legal fees from lawsuits as well as business disruptions. These costs are completely avoidable.

(3)Individual and Organizational Brand Protection.

While OSHA inspections themselves may be unannounced, once completed the results, citations or penalties are typically made public. Employers are typically required to post a copy in the workplace, which contributes to workplace culture. Individual operational management are held directly responsible for citations and penalties irrespective of the fact they are employed by the company. Not a good addition to the resume. Finally, the company itself must deal with the financial and negative press fallout that could impact its brand and ability to connect and do business with other companies.

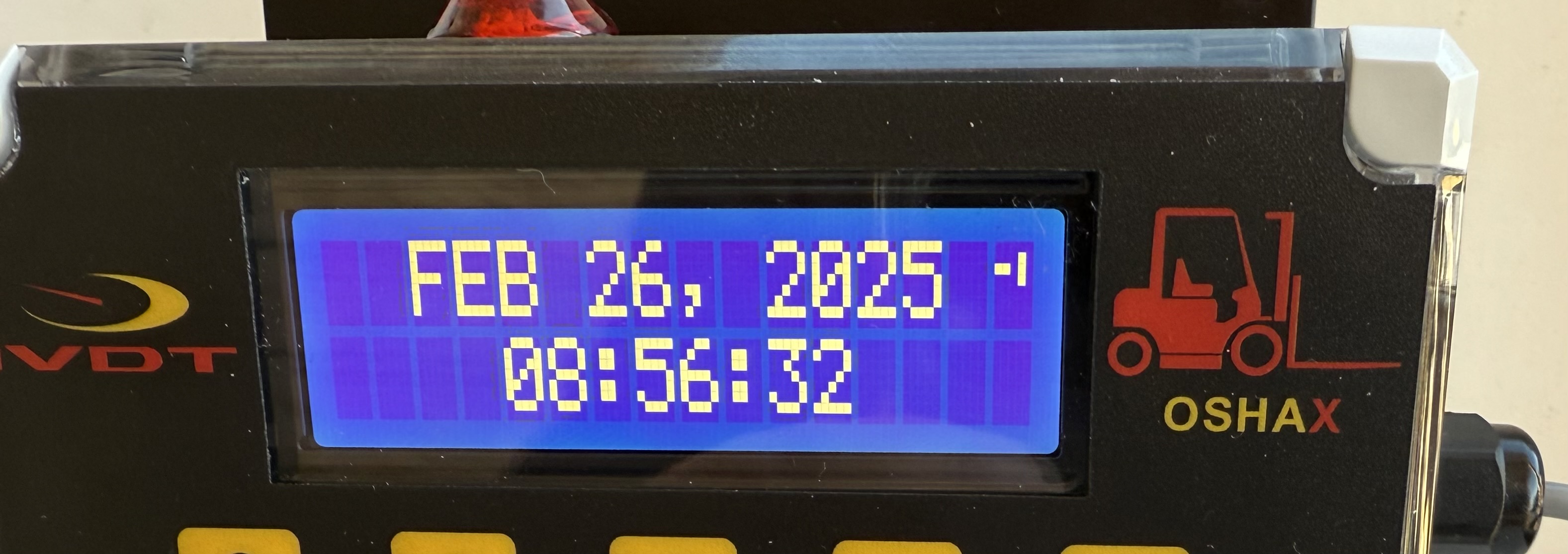

The above financial and legislative nightmare is completely avoidable. OSHAX is a failsafe method for organizations to manage and account for operator forklift pre-safety checks with 100% accuracy and reporting. The system literally installs in approximately 1 hour with supplied universal install brackets and just 2 wires, power and ground for integration with the vehicle. Installs on all makes and models of lift trucks and can even be integrated with aerial lift platforms and other material handling and construction vehicles. OSHAX is an automatic pre-shift safety inspection data logger that starts to work as soon as the lift truck or vehicle is turned on, with no exceptions. The system stores all performed safety checks accounting for vehicle, operator and inspection results chronologically. No lost paper, no forgetting to perform the safety the data is there when you need it most.

Cost Of Safety

Cost Of Safety