Practical Impact Detection That is Simple and Effective

Forklift impact detection and reporting for years have been somewhat confusing and in many cases a rabbit hole for companies that ultimately wanted to use such systems and the material handling dealer who recommend the sell. The age-old dilemma of vehicle and infrastructure damage with no ownership or accountability from the operator still exist but what are the options? Traditional systems fall into 2 categories which present end users and dealers with some difficulty. The first is OEM supported systems which are factory installed in many cases and tied into the ECU of the vehicle. These systems being proprietary are also linked to so many other variables monitoring the operation of the vehicle as well. While comprehensive in detail they are expensive, limited to the brand of the OEM and require monthly support fees. Designed for large fleets of singular brand and installed at the factory at time of order presents aftermarket issues.

What if your lift truck fleet is small and of mixed brands? The second offering for impact detection are aftermarket companies. While these systems can be retrofitted on most brands the issues that we’ve come across are typically in design and support. The accelerometer used to detect impacts is a separate mountable box that must be adhered to the chassis of the lift truck. Sounds simple enough however with the all the different lift truck designs and interpretation from the dealer based installing technician if it is in the wrong spot detections are to sensitive or not effective at all. Often the install is costly with several visits from a dealer technician causing the project to run over budget. End users really have no recourse because the install relies on technical expertise. Support from the manufacturer is always a paid consultation.

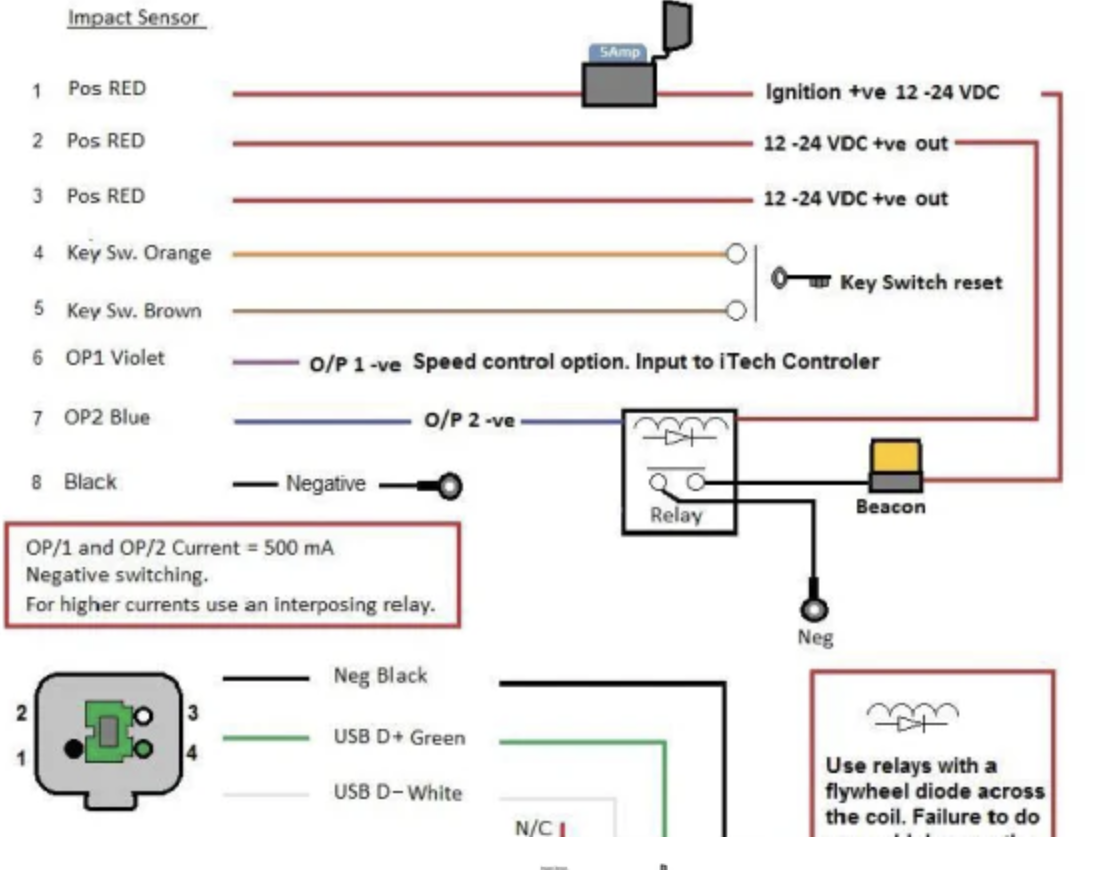

We have designed a complete, and simple impact detection solution that integrates with several of our material handling solutions. The design is that the impaction detection technology is plugged right to the board. Protected in the indicator housing it provides the installing dealer with less to contemplate. The install is always easy, quick and once complete the end user can adjust the settings to specifics of the application. From the onset the design strategy was to be easy and cost effective for end user and selling dealer. For example, take OSHAX a popular onboard impact and safety system. With only two wires for install, power and ground and mounting brackets for each kit the system can be installed in less than two hours.

Once installed the end user can adjust the settings and program the system without the need for costly support. The system is significantly less expensive compared to other manufacturers and OEM systems. Can be installed on any material handling vehicle including construction and aerial lift devices. The system initiates with an operator login followed by a pre-shift safety device. When the safety is completed the OSHAX with impact detection automatically calibrates for both high and low detection.

Download Brochure

Download Brochure