SkidWeigh is North Americas Go to Forklift Scale

Companies with Lighter Loads and No Floor Scale

While an exact, up-to-the-minute number is not available, it is estimated that there are around 1.1 million forklifts in operation in North America, with nearly 900,000 in the United States alone. Loads can range from around 100lbs to over 100,000lbs depending on the industry and capacity rating of the lift truck. However, the average load for all material handling vehicles is 2,400lbs which means that a good majority of those companies use forklifts to load/unload, move and store loads 1000lbs or less. It is a fact that companies with loads less than a 1000lbs are less likely to have a floor scale. With the majority of companies and the majority of forklifts lifting lighter loads without a floor scale that means there is a lot of guess work going on. Do lighter loads mean less revenue loss, less accountability and or less liability? Check out this all to common circumstance that many businesses face and how SkidWeigh’s line of forklift scales can help.

The Company Without a Floor Scale

Ridgeway Components was a mid-sized manufacturer known for cranking out custom aluminum assemblies. Business was steady, orders were consistent, and the production floor ran like a well-oiled machine—or so everyone thought. Despite a tidy warehouse and a disciplined forklift fleet, there was one thing Ridgeway never invested in:a floor scale. Management had always brushed off the idea. “Why would we need one?” the operations manager, Sam, often said. “Our loads are light—anywhere from 200 to 800 pounds. We eyeball it, we’re close enough, and customers haven’t complained.” But behind the scenes, “close enough” was quietly costing Ridgeway real money.

1. Freight Charges Were All Over the Place

Each week, Ridgeway received bills from carriers with adjustments. Their freight estimates often didn’t match the actual weight recorded at the carrier terminal. Sometimes the company overpaid. Other times deliveries were delayed because of reclassification. Accounting chalked it up to “the cost of doing business.”

2. Production Guesswork

Assemblers often needed to know whether they could safely move a pallet themselves or needed equipment. Without accurate weights, workers occasionally overloaded carts or used the wrong lifting method. Nothing catastrophic had happened yet—but close calls were common.

3. Inventory “Weight” Data Was Wrong

Ridgeway tracked production by weight as part of their cost model. But since weights were estimated, inventory data was always a little off. Engineering hated it. Accounting hated it. But nobody had time to drag pallets to the shipping dock’s old borrowed scale at the far end of the building.

The Breaking Point

One Monday morning, a $38,000 shipment was delayed because the carrier flagged Ridgeway for recurring mis declared weights. They warned that future shipments could face penalties.

Sam finally had enough.

“We need a better way to weigh loads. But I’m not installing a floor scale in the middle of the production aisle. So what’s the alternative?”

The SkidWeigh Solution

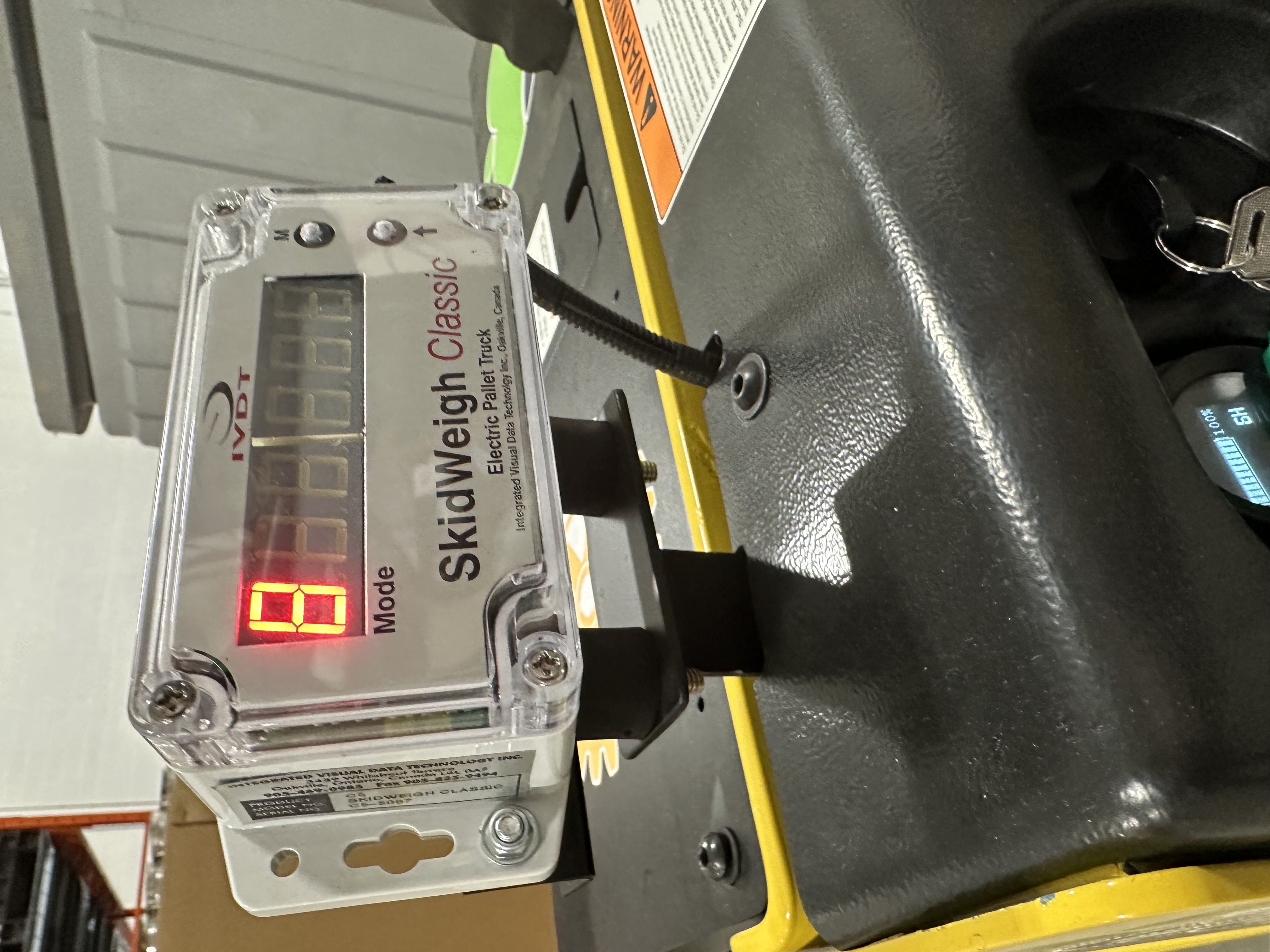

A material handling dealer responsible for the service of Ridgeway’s fleet introduced Sam to IVDT’s SkidWeigh Classic SC2— a system that mounts directly into the hydraulic lift cylinder of the forklift. This tried and tested system does not derate the lift truck, is accurate within 1% of the vehicles capacity and features ‘lift-N-weigh’ technology that produces the load weight within 3 seconds of lifting.

Sam was skeptical.

“While lifting? That can’t be accurate.”

But after a demo, everything changed.

The scale captured the weight of a 550-lb pallet instantly, right on the forklift display—within 0.3% accuracy of the forklift capacity. Operators didn’t have to leave their workflow. They simply lifted, saw the weight, and continued. What’s more is the SC2 offered the operators the accumulative totalling (AT) function allowing them to add loads with the push of a button, eliminating calculators and clipboards. Also standard on all SC series lift truck scales is overload notification which translates to increased safety and peace of mind.

How Ridgeway Transformed Overnight

1. Freight Costs Became Predictable

Loads were actually weighed before shipping. The adjustment fees disappeared. Ridgeway saved more in the first 2 weeks than the cost of the scale itself.

2. Operators Worked Safer and Smarter

Before moving any pallet, drivers knew exactly what it weighed.

No more guesswork.

No more borderline-overloaded carts.

No more “I think it’s fine.”

Safety metrics improved without adding procedures.

3. Real Inventory Data at Last

Production weights were automatically logged from the forklift scale system. Engineering finally had accurate numbers for costing models. Finance stopped chasing weight discrepancies. The ERP system matched reality.

The Reason Material Handling Dealers Trust SkidWeigh

IVDT manufactures several models of lift truck scales to assist with productivity and safety on all sizes of businesses and forklifts including all types of material handling vehicles. The SC2 is just one of the hundreds of options and combinations engineered over the last 40 years that have made the SkidWeigh name the industry standard in onboard weighing for OEM’s, material handling dealers and the businesses that use them. Easy to install, even easier to use and consistent accuracy time over time are what makes SkidWeigh the Go To.

Sam summed it up best:

“Before, we didn’t think we needed a scale because our loads weren’t heavy enough. Turns out, that’s exactly why we needed one—light loads still cost money when they’re wrong.”

Download Brochure

Download Brochure