AC4-OS

AC5-OS

Managing Lift Truck Access

Controlling who operates your equipment can be a challenge in any busy industrial application. Preventing unauthorized use will protect your assets and improve the safety of your operating environment. Finding a system that is functional, durable, and affordable is not only a necessity but a safeguard.

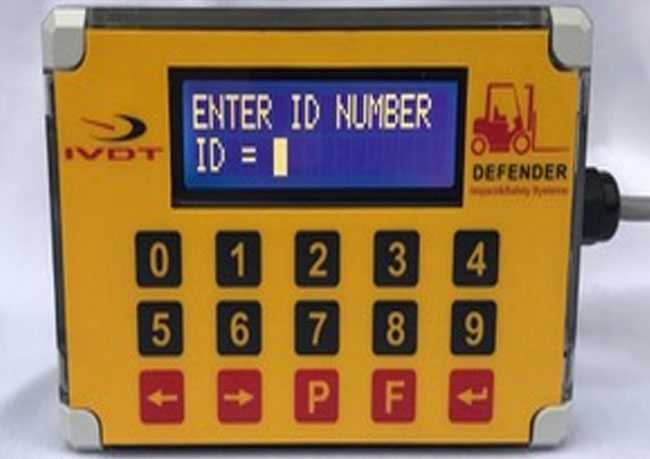

AC4-OS Keypad Operator Access Control

- Automated OSHA safety checklist procedure for all material handling vehicles

- Vehicle will be operational only when OSHA safety checklist session is completed by authorized operator logged into the system during the operational shift (8, 12 hours or daily)

- Safety check activity will be timed to prevent false OSHA safety checklist session events

- LCD Display for visual feedback to the operator of OSHA predetermined safety check procedures and for the management to input the authorized operators ID#s into the system.

- Operator ID#

- Vehicle ID#

- Time / Date

- End time for OSHA safety checklist session

- Total time required for OSHA safety checklist session

- Authorized operator vehicle access control input for up to 150 operators (Up to 3 digits)

- USB automatic data retrieval

- Automatic data archiving

- Excel file reporting format

Functionality and Versatility

Designed to enhance material handling vehicle security for all sizes. The AC4-OS system is particularly suited for medium to small fleets in that it is the first fully automated access control system to combine accountability with OSHA compliant pre-shift safety checks. The system comes standard with keypad operator access but can also be optioned to utilize both RFID proximity cards and fobs.

The system is simple to install and even easier for operators and management to manage and maintain. Standard configuration provides access control to start the truck, and automatic pre-shift safety checks on 8 hour, 12 hour and daily shift intervals. The system also provides a USB data extraction port that allows for ready prepared reports on usage and safety check results stamped with the time of event.

AC5-OS RFID Card Reader Operator Access Control

- Automated OSHA safety checklist procedure for all material handling vehicles

- Vehicle will be operational only when OSHA safety checklist session is completed by authorized operator logged into the system RFID Reader during the operational shift (8, 12 hours or daily)

- Safety check activity will be timed to prevent false OSHA safety checklist session events LCD Display for visual feedback to the operator of OSHA predetermined safety check

- procedures and for the management to input the authorized operators RFID card's into the system.

- Operator ID#

- Vehicle ID#

- Time / Date

- End time for OSHA safety checklist session

- Total time required for OSHA safety checklist session

- Authorized operator vehicle access control RFID Card input for up to 150 operators

- USB automatic data retrieval

- Automatic data archiving

- Excel file reporting format

The AC5-OS system includes RFID Card Reader that is self programming, no additional devices or PC required to add or delete operators cards from the system.