ScanWeight-RF Options & Applications

ScanWeight-RF

- Automatic cycle to measure lift truck freight weight measurement initiated by barcode scan. (Automatic measurement cycle for each individual load weight lifted)

- Lift truck load weight measurement initiated by override push button switch (Application when no barcode scan is available or in case of barcode scanner faulty or not available)

- Automatic OSHA safety check procedure, every 8, 12 hours or daily(Default value set to every 8 Hours)

- OSHA safety check procedure start time(Default value set to 7:00 AM))

- Total time to complete OSHA safety check procedure

- Vehicle ID#

- Operator ID#

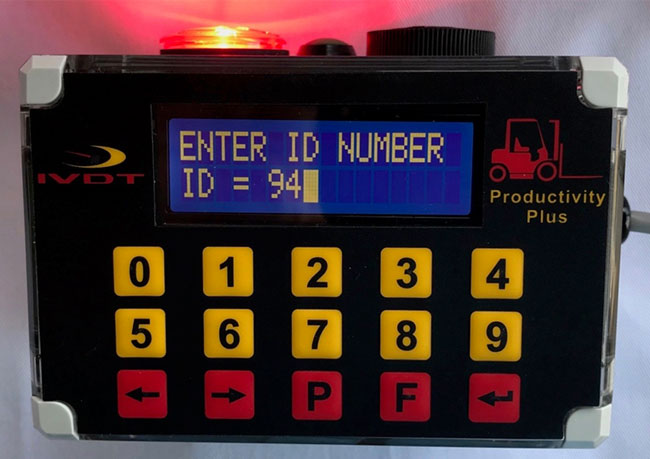

- Operator ID#, keypad input (Up to 250 operators, 1 to 3 digits valid code)

- Barcode scan ID#

- Load weight associated with barcode scan

- Operational session start times

- Real time clock

- * Operator Access ControlExternal visual warning, extra bright strobe LED miniature flashing indicator will be activated and stay on until a valid operator ID# is entered into the system

- * Operator Access ControlExternal loud audio warning message will be activated and repeated until a valid operator ID# is entered

- Factory default operator ID# is 111

- USB port, excel file format recording

- RF module with antenna

- Bluetooth module to communicate with mobile Bluetooth scanner (Bluetooth scanner not included with ScanWeight-RF system)

- Management password protected (Set clock, vehicle ID#, operator ID#)

- Bluetooth pairing procedures with mobile scanner, Auto/Manual/ Inquiry

- 2 Year Warranty

*Note: When ignition switch is turned on the Audio / Visual alert will be activated to remainder operator to log in into the system. Once the operator is logged in the Audio / Visual alert will be turned off. (The ScanWeight system does not disable vehicle operation)

Order Number: ScanWeight-RF

| SkidWeigh ED2-SLL |

|---|

| Compact 4” x 2” x 3” Digital Indicator |

| Large Easy Read Six Digit LED Display |

| No Button Design Easy to Use and Does Not Impede Productivity |

| IP67 Harsh Environment Protective Enclosure |

| Universal Power Supply from 12 to 60 VDC |

| Proprietary and Modular Software for Easy Application Customization |

| Automatic Calibration Process |

| 'Lift-N-Weigh’ Operating Process Works in any Language |

| Operable with Forks, Attachments and Hydraulic Accumulators |

| Two Independent Weighing Channels |

| Reverse Polarity Protection |

| Industry Leading Accuracy and Reliability with +/-1% of Rated Capacity or Better |

| Swiss Manufactured Specifically for the Material Handling Industry |

| 2 Year Warranty |

| Digital Indicator | |

|---|---|

| Housing | ABS NEMA Type 4X, size 120 x 80 x 55 mm |

| Display | Six digits LED display |

| Operating Voltage | 12 to 60 V DC |

| Current Consumption | <80 mA |

| Technology | Micro Controller |

| Communication Interface | RS-232 |

| Connector | Liquid tight straight thru fitting for electrical cable |

| Operating Temperature | -30°C to + 75°C |

| Storage Temperature | -40°C to + 80°C |

| Weight Function Graduations | 1,5 and 10 |

| Weighing Session Sample Rate | 16000 samples |

| Weighing Accuracy | Within +/- 0.1 to 1% of vehicle lifting capacity |

| Weighing Lifting Capacity | Up to 50000 pounds or kg |

| Output Relay | Contact rating 1A, SPDT |

| Internal Buzzer | 60 dB at 30 cm distance |

| Pressure Transducer | |

| Custom Manufactured | Swiss Made |

| Pressure Transducer Port | 1Ž4”-18 NPT male thread |

| Hydraulic Spike Protection | Built in pressure snubber |

| Proof Pressure | 2.5 x range or 6000 PSI |

| Environmental | NEMA 4X |

| Electrical Plug Connection | M12 x 1 metal thread |

| UL Standard | 873 |

| Shock | IEC 60068-2-6 |

| Power Supply | 8 to 33 V DC |

| Insulation Voltage | 500 V DC |

| Response Time | <1ms |

| Load Cycle | <100 Hz |

| Current Consumption | 4mA |

| Reverse Polarity Protection | Yes |

| Over Voltage Protection | Yes |

| Short Circuit Protection | Yes |

| Housing Material | Stainless steel (AISI 303) |

| Weight | 95 g |

| Installation | Unrestricted |

| EMC Conformity | EN 61326-2-3-2006 pressure sensor |

| Temperature Influence On Accuracy | Negligible |

| Exceeding Rapture Pressure | No media egress |

| 3 Wires Electrical Cable | Gauge 18 AWG STC SR-PVC , 1 meter |

| SkidWeigh ED2-SLL | ||

|---|---|---|

| AT | Accumulated Total | Provides ED2-SLL users the ability to calculate the total weight of a series of loads |

| SM | Overload Warning | This option notifies the operator when the load lifted is beyond the rated capacity of the lift truck |

| SM-A | Audio Overload Warning | Same operating principal as the SM except with the inclusion of an audible notification upon overload |

| 2X | Two independent Weighing Channels | Allows ED2-SLL users to use the system on both forks and quick disconnect attachments without recalibration each time |

| SL | Display in % of Lifting Capacity | ED2-SLL system is configured to display the load lifted weight as a percentage of total lifting capacity |

| Printer Interface | Provided the ED2-SLL user the ability to connect a printer to the system for purposes of printed receipt or labelling | |

| SkidWeigh ED2-SLL Possible Configurations | |

|---|---|

| ED2-SLL | Standard weighing system |

| ED2-AT | Standard weighing system with accumulative load weight total |

| ED2-AT-SM | Standard weighing system with accumulative load weight total and visual overload warning |

| ED2-AT-SM-A | Standard weighing system with visual overload warning |

| ED2-SM | Standard weighing system with visual overload warning |

| ED2-SM-A | Standard weighing system with visual and audio overload warning |

| ED2-2X | Standard weighing system with two independent weighing channels |

| ED2-2X-SM | Standard weighing system with two independent weighing channels and visual overload warning for two weighing channels |

| ED2-2X-SM-A | Standard weighing system with two independent weighing channels and visual/ audio overload warning for two weighing channels |

| ED2-2X-AT | Standard weighing system with two independent weighing channels and accumulative load weight total for each weighing channel |

| ED2-SL | Load weighing system showing in % of vehicle lifting capacity |

| ED2-SL-SM | Load weighing system showing in % of vehicle lifting capacity and visual overload warning |

| ED2-SL-SM-A | Load weighing system showing in % of vehicle lifting capacity and visual/audio overload warning |

| ED2-SL-2X | Two independent load weighing system showing in % of vehicle lifting capacity |

| ED2-SL-2X-SM | Two independent load weighing system showing in % of vehicle lifting capacity with visual overload warning for each channel |

| ED2-SL-2X-SM-A | Two independent load weighing system showing in % of vehicle lifting capacity with visual / audio overload warning for each channel |

| ED2-Print | Standard weighing system with accumulative load weight total with interface for RS-232 onboard printer (RS-232 cable and power cable included) |