SkidWeigh Plus ED Series: Productivity and Safety

A Complete, Simple and Sustainable Approach to Forklift Safety

With over 200 locations across Canada and 2300 employees one of the largest industrial gas and technology providers in the world was taking their forklift fleet management to the next level. They had decided that the best practice going forward was to implement consistency across the board, this included selection of standardized vehicles, a number of third-party safety tests and the addition of a vehicle management system to protect operators, the vehicle asset and improve productivity. The selection of what system to incorporate was based on the following criteria. Ease of use without internal complications that burden other departments, ie. IT. One that the operator and site management could easily navigate to acquire results, they were not interested in managing online graphs and pie charts, just the facts. And finally, they wanted a system and supplier that could provide training and support when needed without the need to open a ‘heat ticket’ and wait for an answer. Working with the pivot dealer out of Ontario we were selected and introduced the SkidWeigh Plus ED3-IM safety management system.

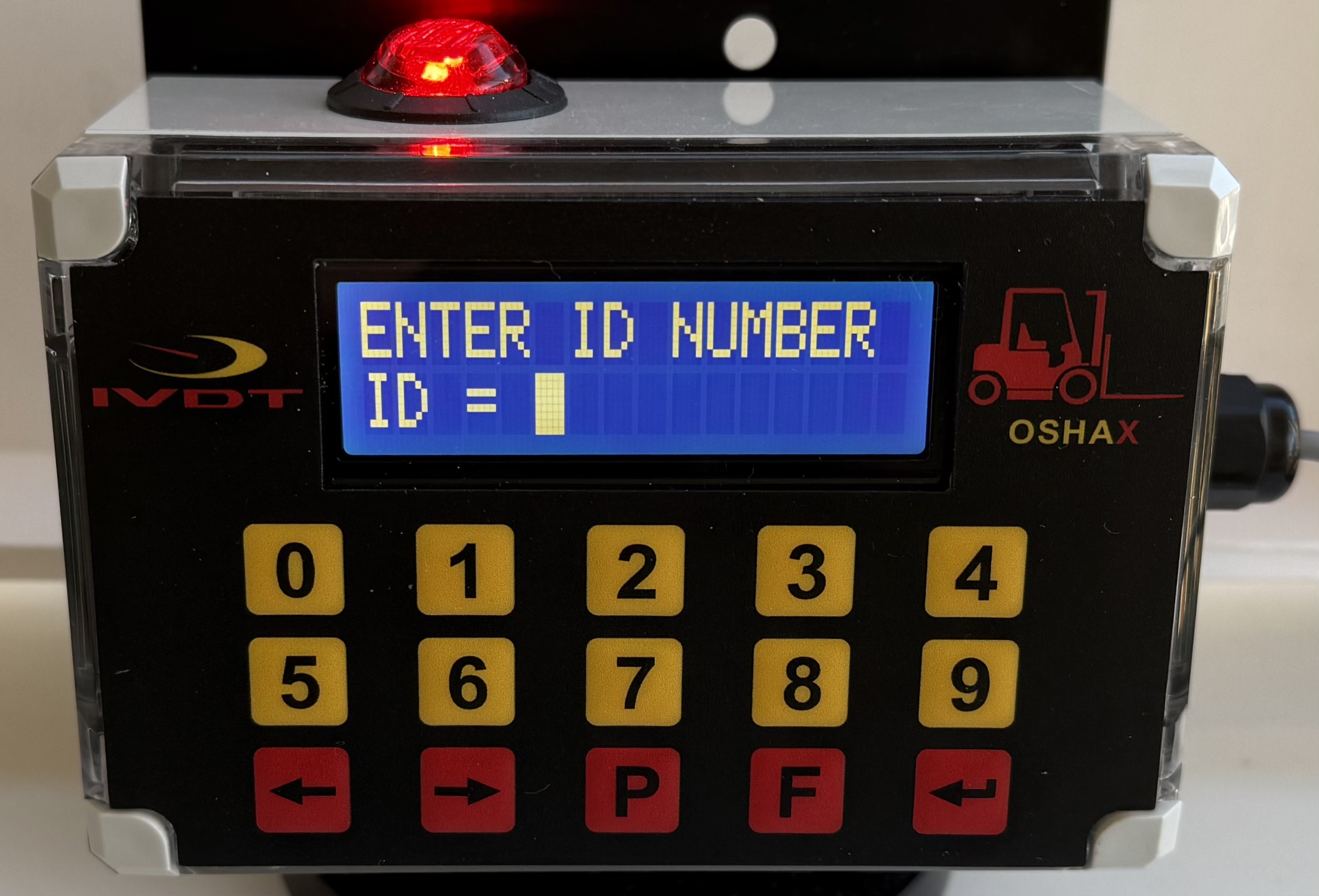

Access Control:

The SkidWeigh Plus ED3 system allows users to identify and control who has access to the lift truck. This ensures that only certified and or authorized users have access to the lift truck. This includes operators, management and outside contractors. This feature is also critical when reading reports as it clearly states who initiated the event to be analyzed.

Pre-Shift Safety Check:

Before the lift truck is to be to be put into commission and enter its shift an operator must perform a safety check in accordance with OSHA and MOL standards. The ED3 system automatically prompts the operator to perform the pre-shift safety check and records the pass or fail results. Moreover, it also reports the time it took to perform the safety check to ensure that due diligence is taken during the inspection. Depending on the location and hours of operation the system can account for single daily checks or multiple shifts in intervals of 8 or 12 hours.

Impact Notification:

With open yards and inside distribution that can include obstacles such as rail access, cross dock applications, custom design infrastructure for housing gas cylinders there are several tight maneuvers that must be approached with caution to avoid damage and operator safety. The two-tier impact notification allows the company to set an operational threshold to ensure just that. The high impact is the threshold not to be surpassed and warrants a management inspection once surpassed. The low impact is a warning to the operator that they are getting close to that threshold therefore providing a pre-warning to avoid the high impact. This approach to impact management is less adversarial and not the typical ‘trying to catch you in the act’ that many systems deploy. Instead, it promotes a safety culture of providing tools to achieve agree upon benchmarks.

ED Weighing Suite:

The ED3 provides the end user a multitude of safety and productivity options that include the following. Hydraulic pressure transducer weighing which allows the operator to weigh pallets and loads to better than +/-1% of vehicle capacity accuracy, no derating of the lift truck and the only stable consistent calibration in the market. This means that the business can focus on usage and integration of the scale and not on testing it against a floor scale all the time. The ED3 weighing suite also allows them to add multiple loads with the Accumulate Totaling (AT) function. Overload notification that ensures that the vehicle capacity and or racking weight ratings are respected. When a programmed weight threshold is surpassed, an audible strobe sounds within seconds to ensure safety. Finally tare input is also offered which is particularly useful in this application due to the custom bins and support structures for the various cylinders that are transported. The ability to put the tare weight into the ED3 allows the operator to get the net weight quick.

Data Collection and Export:

The SkidWeigh Plus ED3 system collects all the data and time stamps the event with the assignment of a vehicle number. The data exports easily with a USB and displays a complete event summary in excels formatting.

Simple to use the SkidWeigh Plus ED3-IM is just as simple to install. Requiring approximately 2.5 hours of install time by a qualified technician or comparable skill set. The system is designed to be end user friendly it is very intuitive with step by step instructions so that costly external support can be avoided.

Downloads Brochures

Downloads Brochures