Automotive Manufacturing Uses InfoHUBX to Push Data

A major Japanese auto manufacturer with several plants in North America was looking for a way to quality control their JIT, ‘just in time’ process of shipping and receiving parts. For details, please click here The ability to uncover lost or overlooked parts in shipping containers was already supported with SkidWeigh onboard scale systems. However, this auto manufacture was looking for an automatic solution that would allow stakeholders access to the information without travel through the large multi-facility plants and the need to manually process and analyze data.

With the addition of a SkidWeigh Classic Plus ED3C and the InfoHUBX communication server the ability to access data from anywhere in the plant was a game changer. The ED3C utilized a scanner that would code and identify each load lifted and prompt the operator to weigh the load. The ED3C would then through 900MHz license free ISM band long distance RF modem will send the information automatically to the InfoHUBX server.

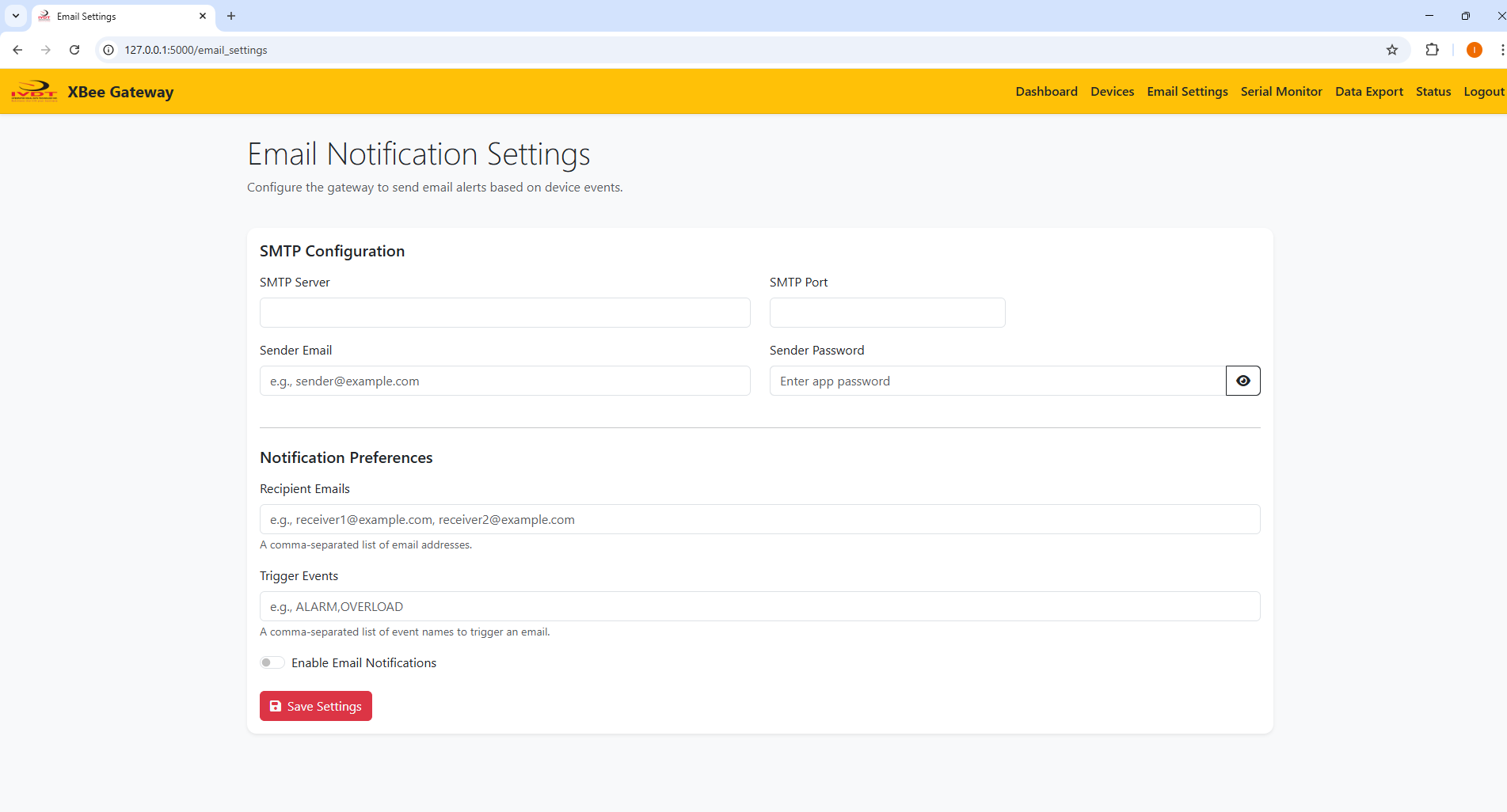

The InfoHUBX would then process the weight data in 2 specifically useful actions. The first, InfoHUBX provides an interactive easy to use computer interface that displays all required events, in this case weight with the load identifier and time stamp it for sequencing and archival. The second and very important function is the ability to send email notification when a weight has been surpassed. In this case the overload notification on the ED3C was set to 1015 the respective weight of parts containers empty. When that weight threshold is surpassed it sends an email notification to record the details of the lift. In addition, the ED3C also has an operator supported audio visual alarm to indicate overload. With access to this information management and lift truck operators are working in real time with better reactive awareness to the production requirements of manufacturing.

InfoHUBX is a standalone network connection that does not require Wi-Fi or cloud-based support, eliminating costly monthly fees and or security risks. The InfoHUBX system is utilizing a powerful DiGi XBEE-PRO modem (Regulatory approvals in USA, Canada and Australia) and laptop PC which serves as the data center. The system is virtually plug and play with the addition of an IP address and the input of an SMTP mail server compatible with all modern network servers.

The system communicates with all ED3 series IVDT onboard systems and captures and displays data on a variety of weight captures, impacts and OSHA safety information, vehicle operational idling / downtime events as well as operator identification and vehicle unit number. All data is recognized in real time with a time stamp. IT departments champion the system for its ease of connectivity and non-supportive reliability in the background. Operation managers advocate for InfoHUBX because it has superior outdoor LOS range of up to 28 miles*, indoor range of more than 2000 feet with Digi Meash protocol and fully automatic real-time communication / reports into the daily operations of any material handling operational facilities.

Download Brochure

Download Brochure